With the rapid development of the Internet of Things technology, RFID (radio frequency identification) technology, as one of the key technologies, is increasingly widely used in the field of intelligent warehousing. RFID technology implements non-contact data transmission through radio waves to realize automatic identification and tracking of target objects. Among them, RFID reader antenna is an important part of the system, and its performance directly affects the identification efficiency, accuracy and coverage of the RFID system. This paper will deeply analyze the application of RFID reader antenna in smart storage from a professional perspective, and discuss its technical principles, application advantages and practical cases.

First, RFID technology overview

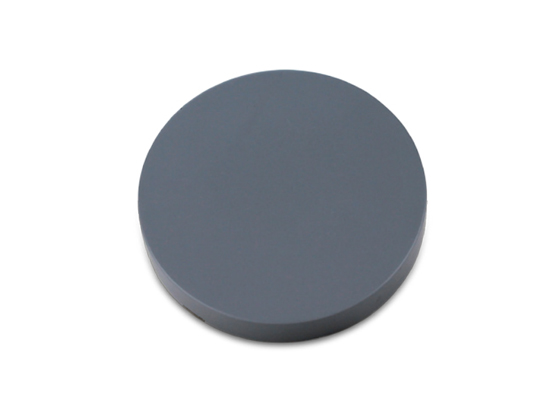

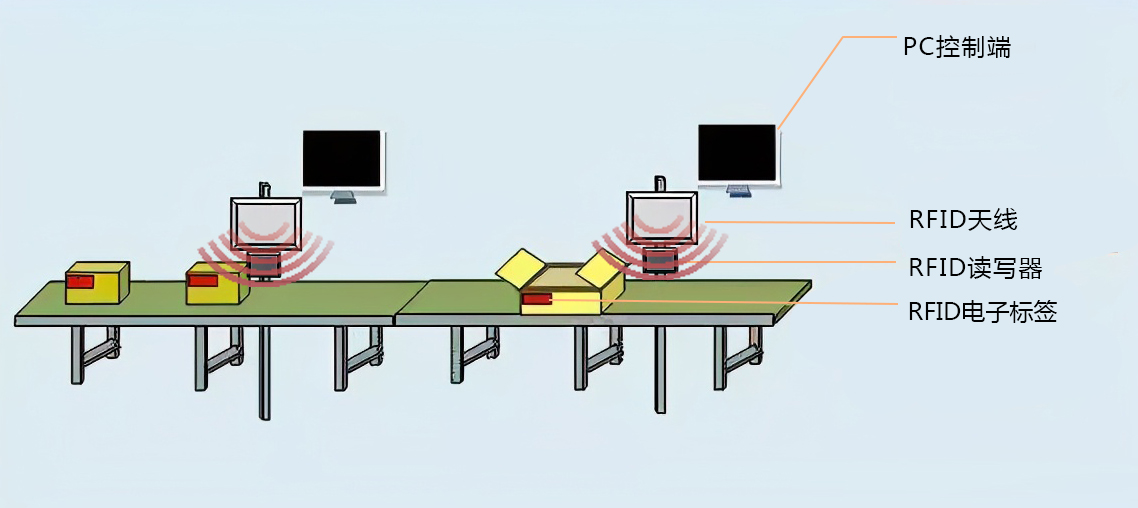

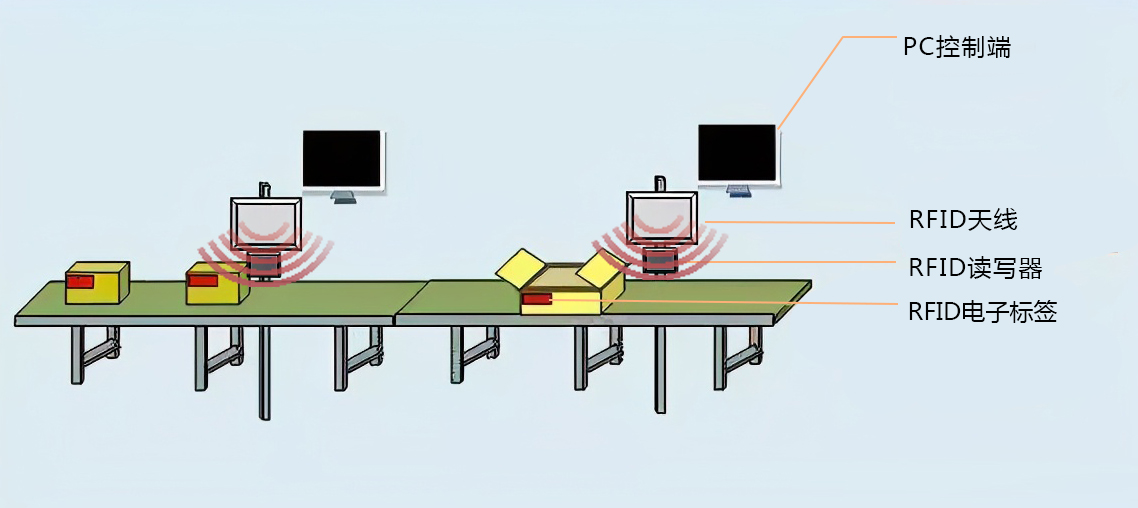

RFID technology is a communication technology that uses radio waves for non-contact automatic identification and data exchange. It consists of three parts: RFID tag, reader (including antenna) and data processing system. The RFID tag is attached to the identified object and stores the relevant information of the object; The reader transmits an RF signal through the antenna, activates the tag and reads its stored information, which is then transmitted to the data processing system for processing. Compared with traditional identification methods such as bar codes and two-dimensional codes, RFID technology has the advantages of batch identification, non-contact reading, large data storage capacity, and strong environmental adaptability.

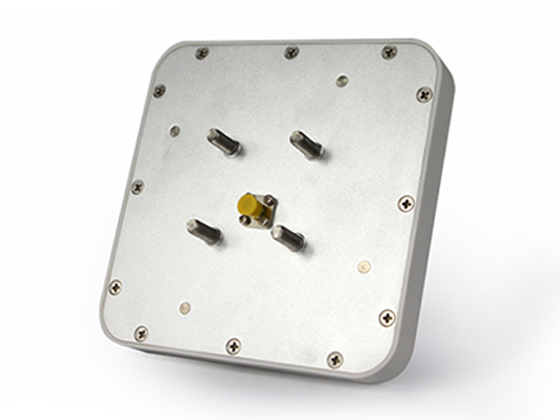

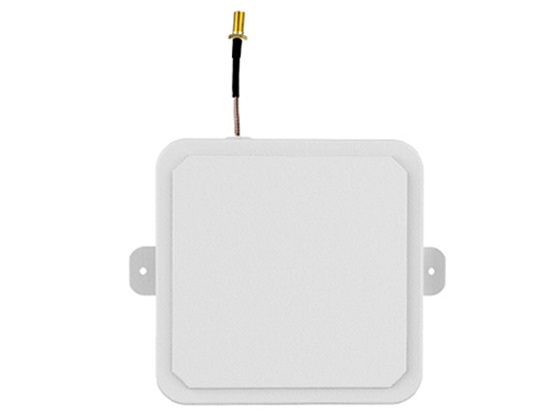

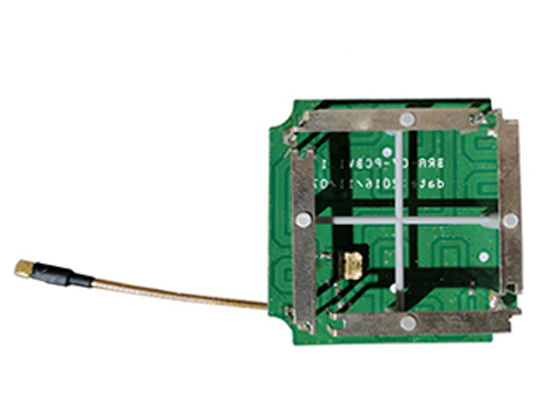

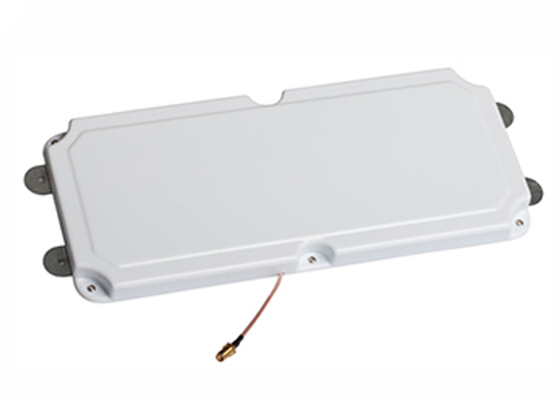

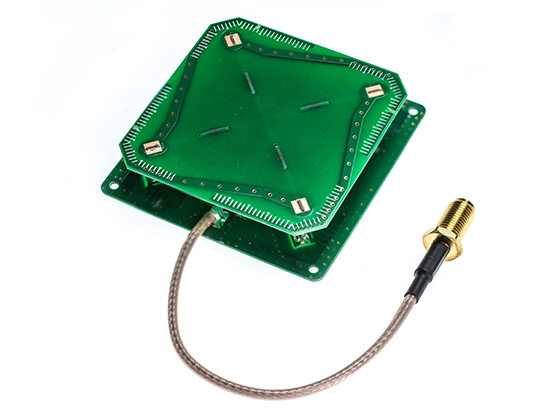

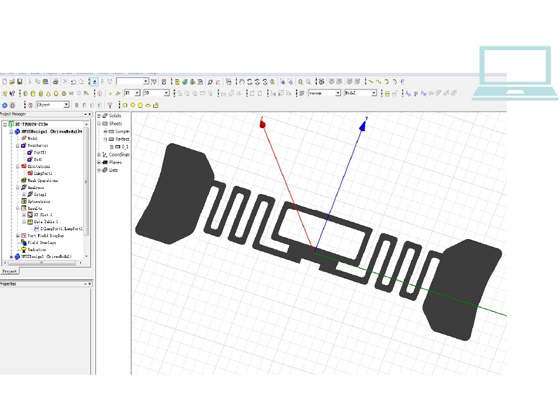

Second, the working principle of RFID reader antenna

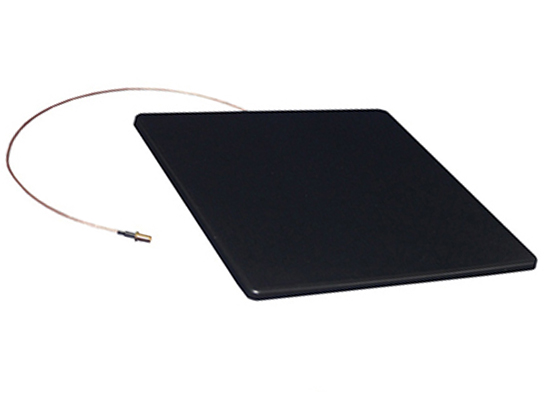

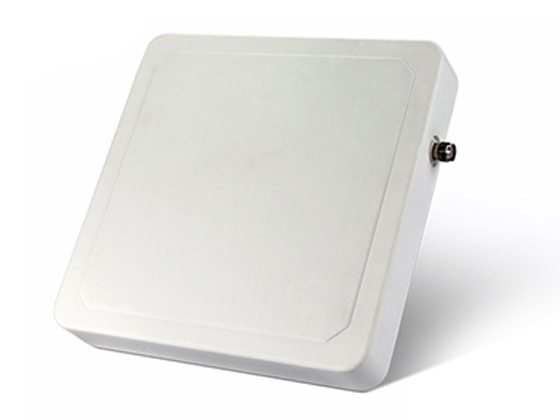

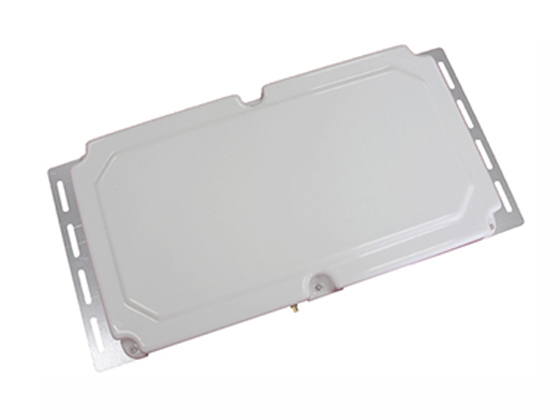

RFID reader antenna is a key component used to transmit and receive radio frequency signals in RFID system, and its performance directly affects the identification effect and coverage of the system. The design of RFID antennas needs to consider multiple factors such as frequency, polarization mode, gain, and directivity to ensure the effective transmission and reception of signals.

Frequency selection

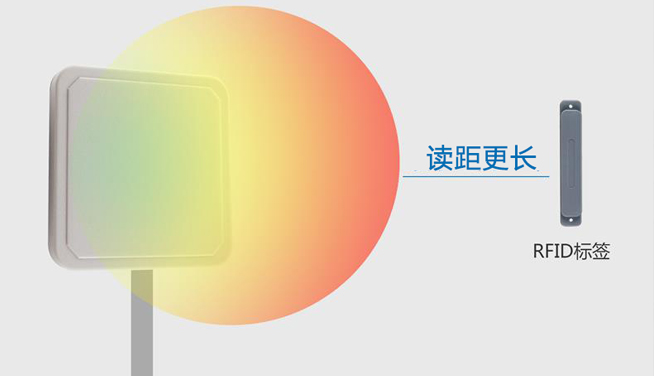

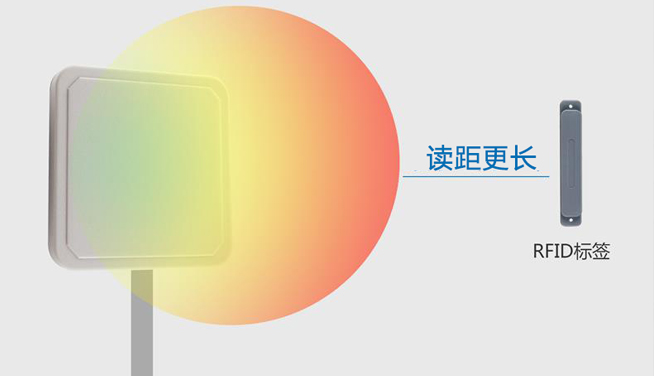

RFID technology is used in a wide range of frequencies, including low frequency (LF), high frequency (HF), and ultra-high frequency (UHF). Antennas of different frequency bands have different characteristics, such as transmission distance and anti-interference ability. In smart warehousing, ultra-high frequency (UHF) RFID technology is widely used because of its long read distance and high data transmission rate.

Polarization mode

The polarization mode of an antenna determines the spatial distribution of its radiated electric field. In RFID systems, the common polarization modes are wired polarization and circular polarization. Selecting the proper polarization mode can optimize the radiation characteristics of the antenna and improve the recognition efficiency.

Gain and directivity

The gain of the antenna reflects the concentration of its radiation energy. The higher the gain, the more concentrated the radiation energy and the farther the reading distance. At the same time, the directivity of the antenna also affects its coverage. In smart storage, it is usually necessary to choose the appropriate antenna gain and directivity according to the layout of the warehouse and the placement of the goods to achieve the best identification effect.

Third, the application advantages of RFID reader antenna in smart storage

1. Real-time tracking and positioning

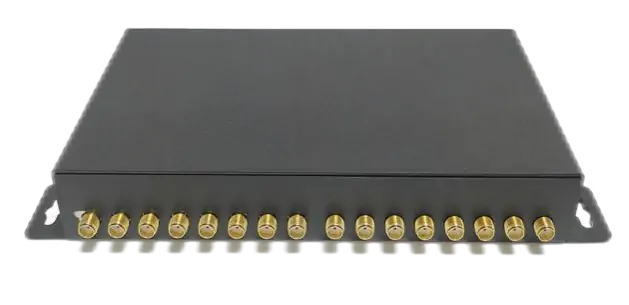

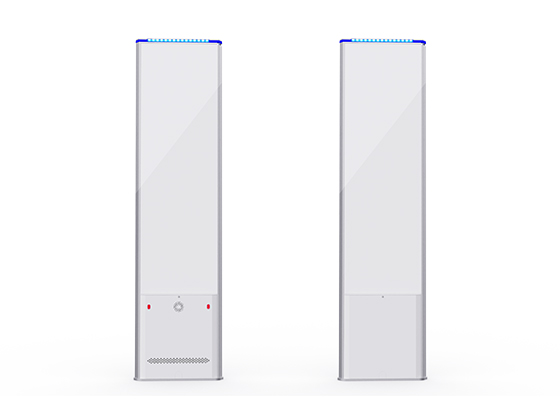

By attaching RFID tags to the goods and arranging RFID reader antennas in the warehouse, real-time tracking and positioning of the goods can be realized. RFID reader antenna can read label information at a long distance and penetrate, and can update inventory data in real time without manual intervention, which greatly improves the accuracy and efficiency of inventory management.

2, automatic inventory

Traditional stock counting requires a lot of manpower and time, and is prone to errors. After the use of RFID technology, only through the handheld RFID reader or fixed RFID reader antenna, you can quickly complete the inventory of the entire warehouse. RFID technology can identify multiple tags at the same time, greatly improving the speed and accuracy of inventory, and reducing labor costs.

3, improve loading and unloading efficiency

During the loading and unloading process of the warehouse, the RFID reader antenna can quickly identify and confirm the cargo information, avoiding the traditional manual confirmation process. This not only reduces operating time, but also reduces the risk of human error and improves loading and unloading efficiency.

4. Optimize inventory management

RFID technology can monitor inventory status in real time, including inventory quantity, location distribution, shelf life and other key information. When the stock is lower than the safety stock, the system can automatically issue an early warning to remind the enterprise to replenish the stock in time to avoid the risk of stock shortage. At the same time, RFID technology can also help enterprises analyze inventory turnover, dead sales and other business indicators, to provide data support for inventory optimization.

Iv. Actual case analysis

Case 1: E-commerce warehousing management

In the e-commerce industry, with the surge in order volume, the pressure of warehouse management is increasing. An e-commerce giant has introduced an automated sorting system based on RFID technology in its logistics center. When the goods are stored, the RFID reader antenna automatically scans the labels on the goods and enters the goods information into the system. When the order is generated, the system automatically plans the sorting path according to the order information, and guides the sorting robot or automated equipment to find and sort the goods quickly and accurately through RFID technology. This system greatly improves sorting efficiency and accuracy, reduces labor costs, and provides e-commerce companies with faster order processing capabilities.

Case 2: Material management in manufacturing industry

In the manufacturing industry, warehouse management of raw materials and semi-finished products is crucial to production efficiency and product quality. A manufacturing enterprise has realized automated warehousing and warehousing management by attaching RFID tags to raw materials and semi-finished products, and arranging RFID reader antennas in the warehouse. Through RFID technology, enterprises can grasp the location, quantity and status information of materials in real time, improve the accuracy of material tracking and positioning, and reduce the error caused by human operation. At the same time, RFID technology also helps enterprises optimize the production process and improve production efficiency.

RFID reader antenna, as a key component in RFID system, plays an important role in intelligent storage. Through the advantages of real-time tracking and positioning, automated inventory counting, improved loading and unloading efficiency, and optimized inventory management, RFID technology has revolutionized warehouse management. In the future, with the continuous development of technology and the reduction of costs, RFID technology will be widely used in more fields, bring greater value to enterprises, and promote the intelligent upgrade of warehouse management.