In today's rapidly developing e-commerce industry, clothing e-commerce, as an important part of it, is facing the growing order volume and inventory management challenges. How to efficiently and accurately manage inventory, reduce human error, and improve warehouse operation efficiency has become a problem that many clothing e-commerce enterprises need to solve. This article will introduce in detail how a clothing e-commerce enterprise can realize the intelligent upgrade of warehouse management through the introduction of RFID handheld readers and tags, so as to effectively solve the problem of inventory and improve the overall operational efficiency.

Customer background and challenges

Since its establishment, the clothing e-commerce enterprise has stood out in the fierce market competition with its unique design concept and high-quality customer service, and has rapidly developed into a bright star in the industry. However, with the rapid expansion of business scale, warehouse management has become a bottleneck restricting its further development. The traditional manual inventory is time-consuming and has a high error rate, especially during the promotion period, the inventory fluctuates greatly, and the manual inventory can hardly achieve real-time accuracy, resulting in frequent problems such as order delay, inventory backlog or shortage, which seriously affects the customer experience and the operation efficiency of the enterprise.

Solution exploration

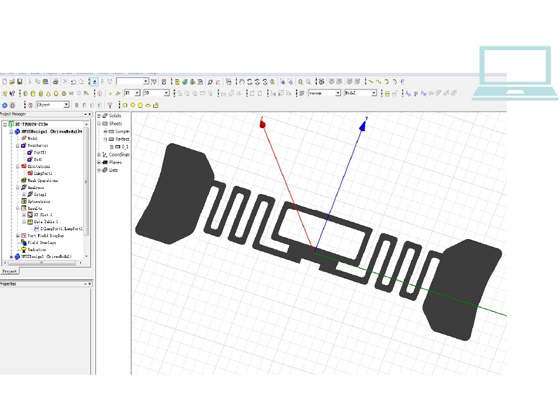

Faced with the above challenges, the clothing e-commerce company began to actively look for technical solutions that can improve the efficiency of warehouse management. At an industry exchange meeting, the person in charge of the enterprise noted the application cases of RFID (radio frequency identification) technology in the field of warehousing and logistics, especially the combination of RFID handheld machines and tags, which can greatly improve the efficiency and accuracy of inventory counting. After in-depth investigation and comparison, the company finally selected Bowei intelligent procurement RFID handheld phones and supporting labels as a key tool to upgrade warehouse management.

RFID handheld and tag application implementation process

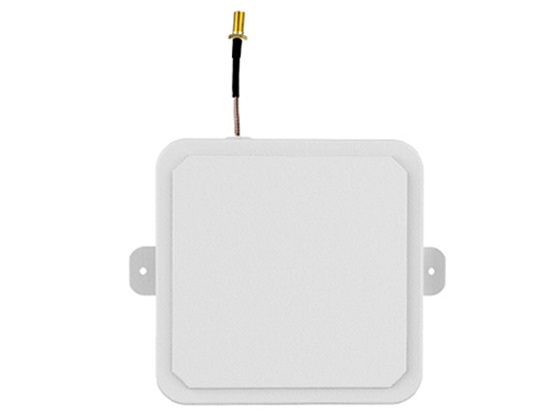

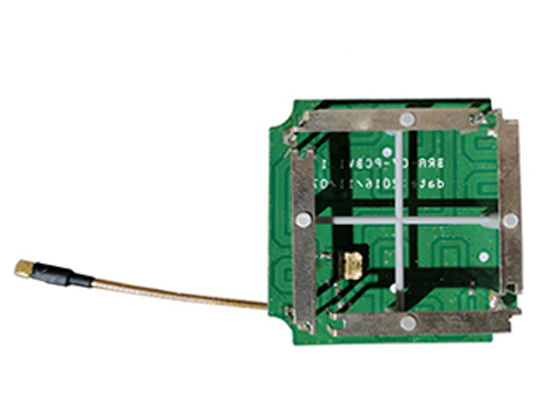

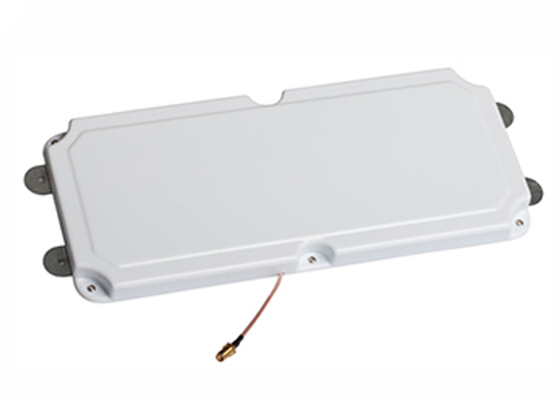

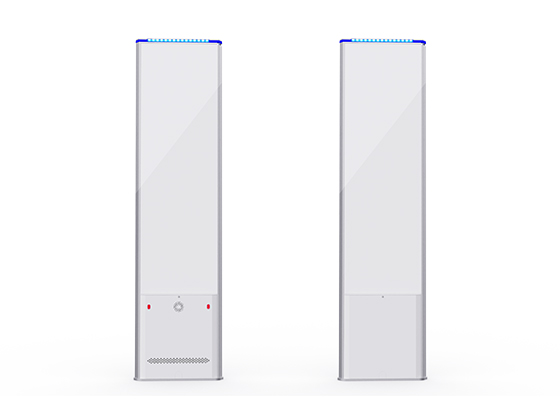

1, label paste: In the clothing e-commerce warehouse, each product or each stock unit will be affixed with an RFID tag. These labels contain the product's unique identification, style, size, color and other key information.

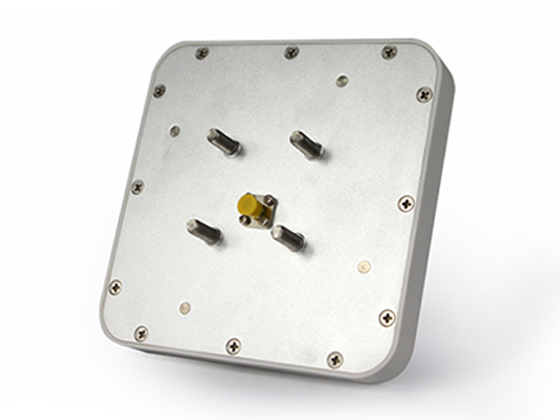

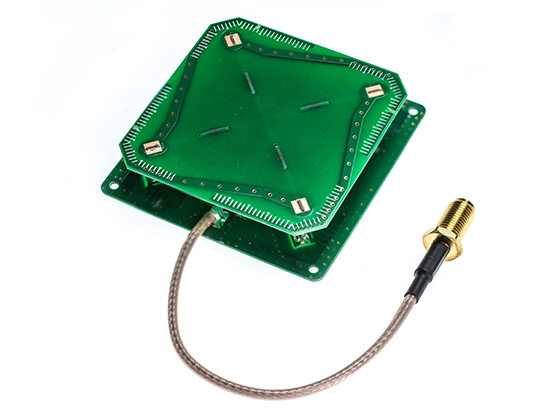

2, handheld scanning: warehouse staff use RFID handheld to scan inventory goods. The handset automatically reads the information in the tag and compares it to the data in the back-office management system.

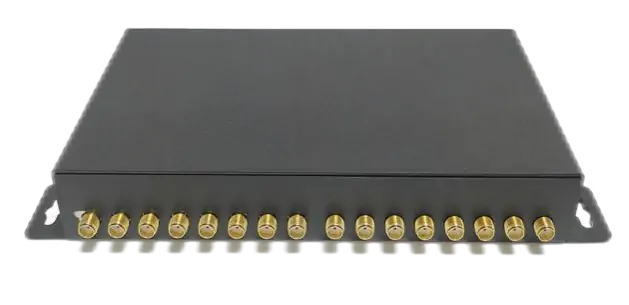

3, data upload and update: read data will be uploaded to the background management system in real time. The system will automatically update the inventory status based on this data, including the quantity of goods, location and other information.

4, real-time monitoring and early warning: the background management system has real-time monitoring function, can display the dynamic changes of inventory goods in real time. When the stock quantity is lower than the preset safety stock, the system will automatically issue an early warning to remind the warehouse staff to replenish the stock in time.

Remarkable results

After several months of practical application, the warehouse management efficiency of the clothing e-commerce enterprise has been significantly improved:

1, inventory efficiency improvement: in the past, it took several days or even a week to complete the inventory of the whole warehouse, and now it only takes a few hours to complete, greatly shortening the inventory cycle and reducing the warehouse downtime.

2, accuracy improvement: RFID technology to achieve real-time update and high accuracy of inventory data, error rate is almost reduced to zero, effectively avoiding order delays and customer complaints caused by inaccurate inventory information.

3. Reduce operating costs: Automated inventory reduces manpower needs and reduces labor costs; At the same time, due to the improvement of inventory accuracy, the loss caused by inventory overhang or stock shortage is reduced, and the overall operating cost is effectively controlled.

4, customer satisfaction: faster order processing speed and higher inventory accuracy, directly enhance the customer's shopping experience, enhance brand loyalty.

With the in-depth application of RFID technology in warehouse management, the apparel e-commerce enterprise is planning to further expand the application scope of RFID technology, such as the introduction of intelligent shelves, automatic tracking and positioning of goods, etc., in order to build a more intelligent and automated warehousing and logistics system. At the same time, the company will continue to pay attention to the latest development of RFID technology, constantly optimize the existing system, and maintain its competitive advantage in the field of clothing e-commerce.

In short, by introducing RFID handheld devices and labels, this clothing e-commerce enterprise not only successfully solved the inventory problem, but also achieved a comprehensive upgrade of warehouse management, laying a solid foundation for the sustainable development of the enterprise and market expansion. The application of RFID technology undoubtedly provides a new paradigm of efficient and intelligent warehouse management for the apparel e-commerce industry.