- Home

-

Products RFID Antenna Series Integrated RFID Readers Fixed RFID Readers UHF Gate Readers Handheld RFID Readers RFID Tags Smart Device RFID Software and

CustomizationRFID Antenna SeriesProduct ModelBRA-01CR

9dBic Outdoor RFID Antenna

BRA-01L

9dBic Outdoor RFID Antenna

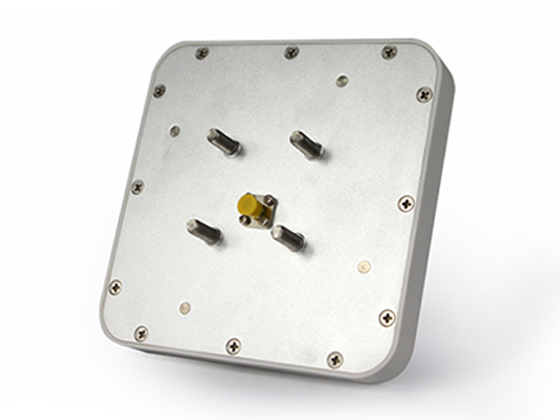

BRA-01SR

8.5dBic Outdoor RFID Antenna

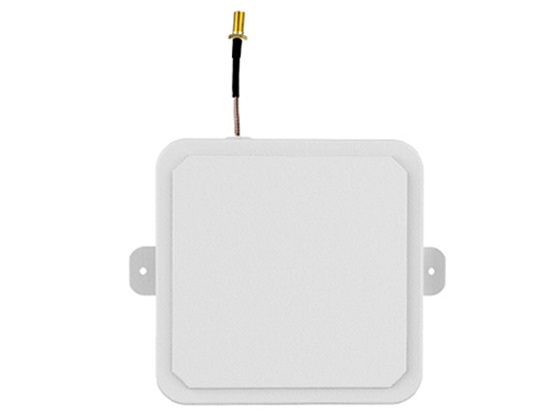

BRA-02CR

6dBic Outdoor RFID Antenna

BRA-02SR

6dBic Outdoor RFID Antenna

BRA-02D

5.5dBic Indoor RFID Antenna

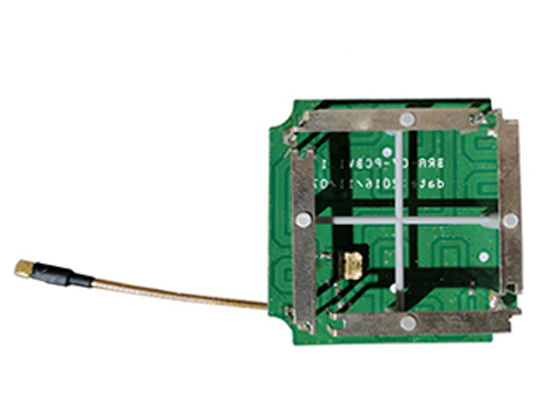

BRA-07

Handheld Reader Antenna

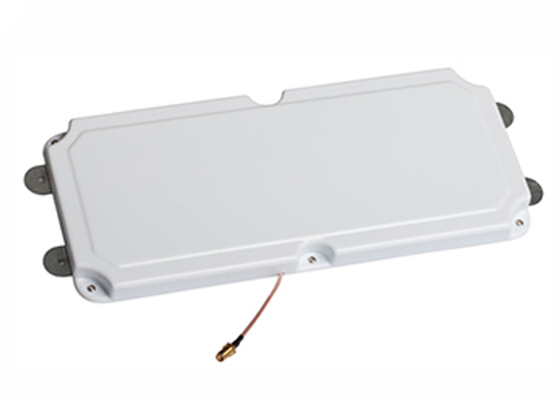

BRA-08

8dBic Narrow Beam Antenna

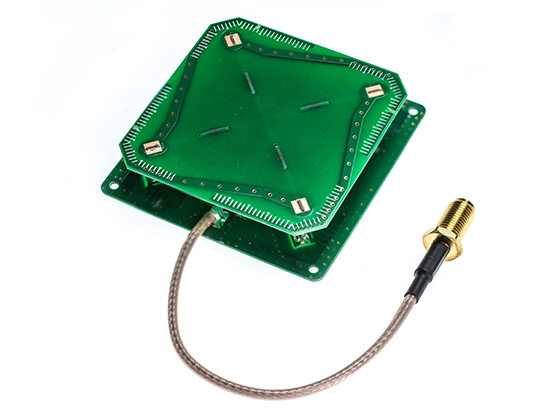

BRA-09

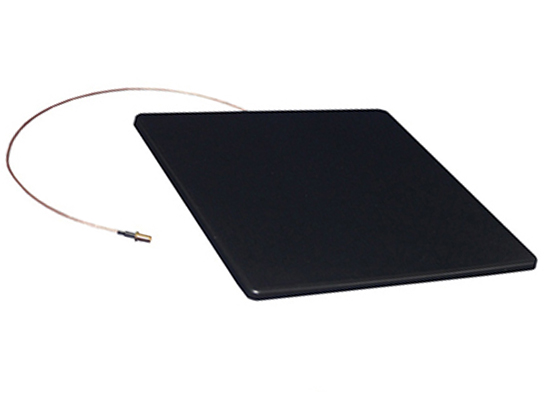

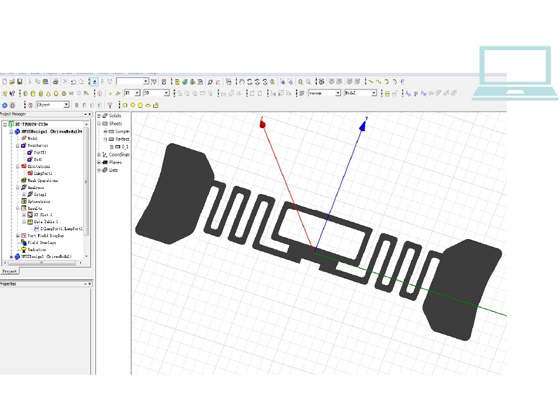

Near-field RFID Antenna

BRA-10

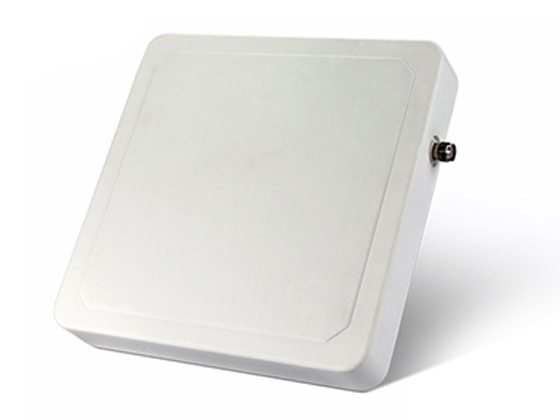

6dBi Narrow Beam Antenna

BRA-15

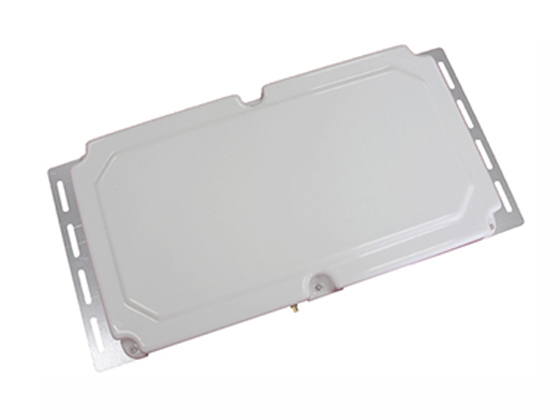

8dBic Outdoor RFID Antenna

BRA-16

Narrow Beam RFID Antenna

BRA-20

Handheld Reader Antenna

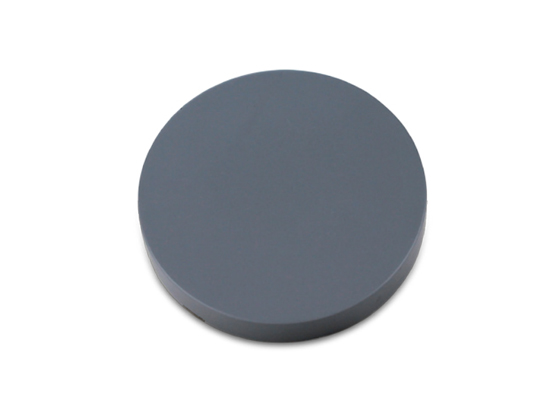

BRA-21

Underground RFID Antenna

BRA-31

8.5dBic Narrow beam Antenna

BRA-49

12dBi Linear Antenna

BRA-50

8dBic Indoor Antenna

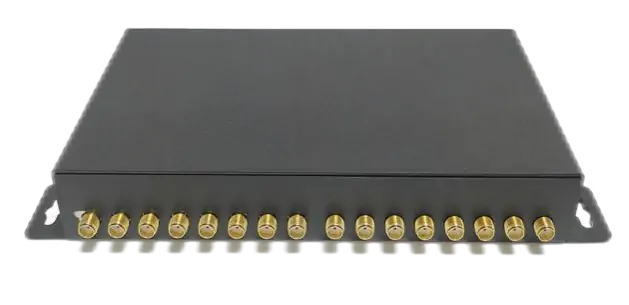

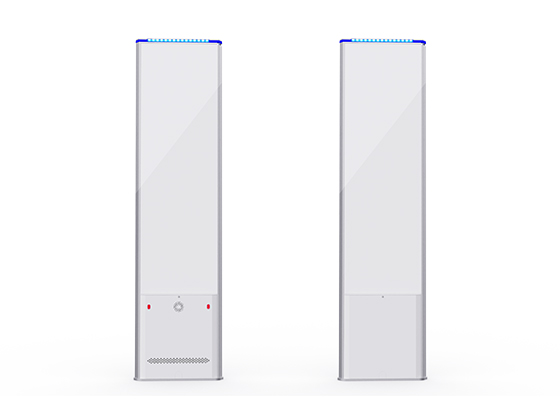

Integrated RFID ReadersProduct ModelFixed RFID ReadersProduct ModelUHF Gate ReadersProduct ModelHandheld RFID ReadersProduct ModelRFID TagsProduct ModelBRT-01

ABS RFID Tag

BRT-02

Ceramic blank card

BRT-03

PVC blank card

BRT-04

Ceramic Anti-Metal RFID Tag

BRT-05

Ceramic Anti-Metal RFID Tag

BRT-06

Ceramic Anti-Metal RFID Tag

BRT-23

Library / Archives RFID Tag

BRT-25

Wristband RFID Tag

BRT-26

Underground RFID Tag

BRT-34

High Temperature RFID Tag

BRT-6535

Flexible Anti- Metal Tag

BRT-7015

Laundry RFID Tag

Smart DeviceProduct ModelRFID Software and

CustomizationProduct Model -

Applications - News

- Partners

- Support

- About Us