With the rapid development of the logistics industry and the enhancement of environmental awareness, turnover box is an important tool in the logistics supply chain, and its management efficiency and accuracy are crucial to improve the overall operational efficiency, reduce costs, and achieve green logistics. RFID (Radio Frequency Identification) technology, as a non-contact automatic identification technology, has shown great application potential in turnover box management. This paper will discuss the application of RFID technology in turnover box management from the basic principle of RFID technology, the specific application in turnover box management, advantages and practical cases.

The basic principle of RFID technology

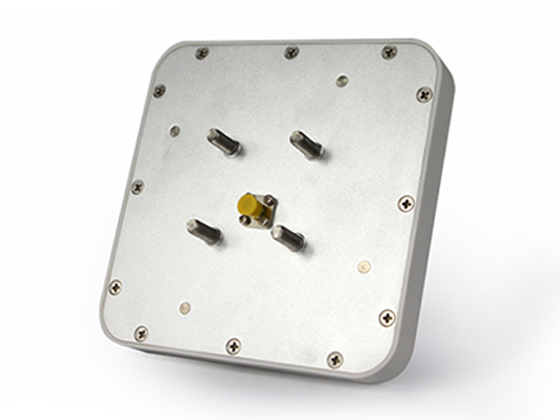

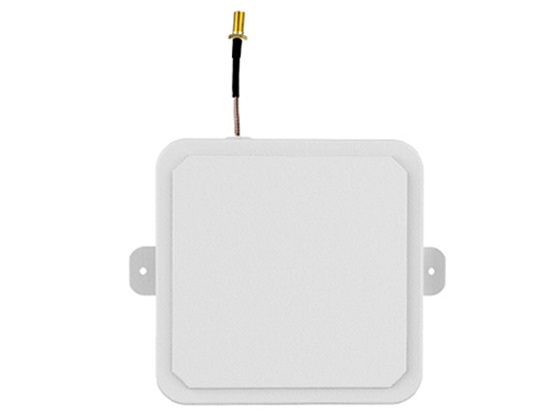

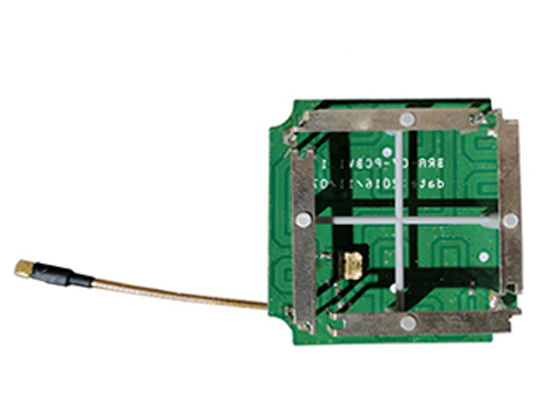

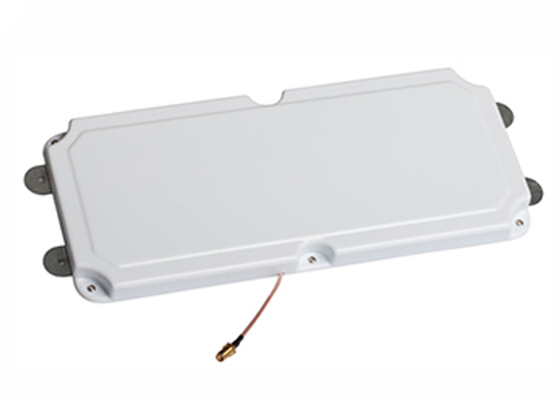

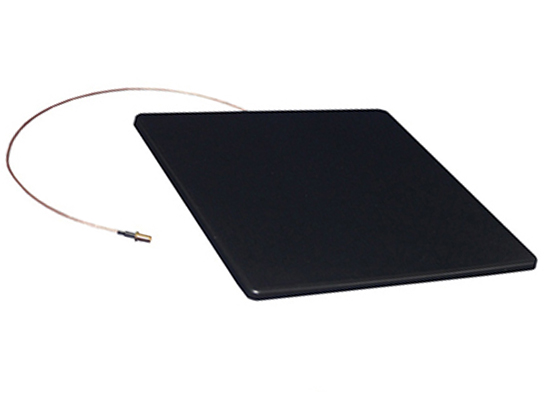

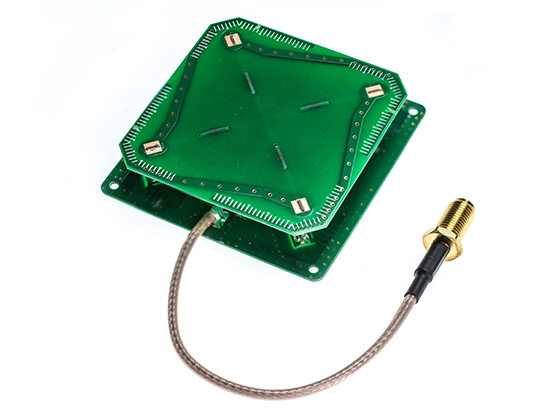

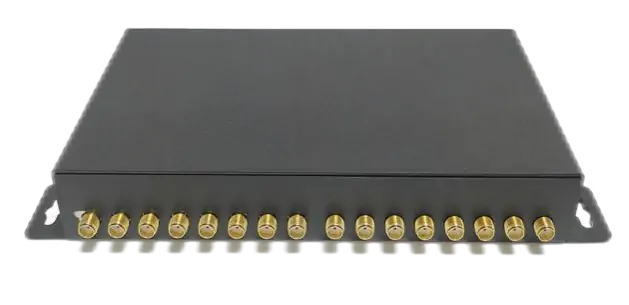

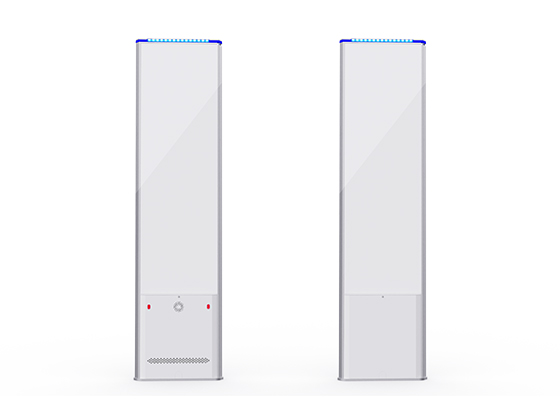

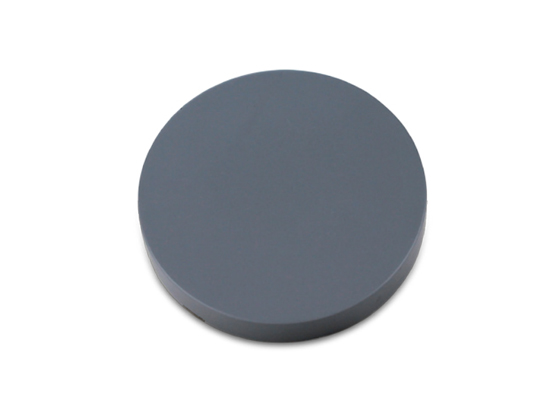

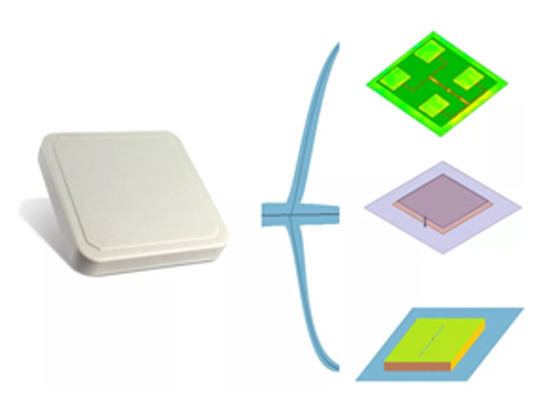

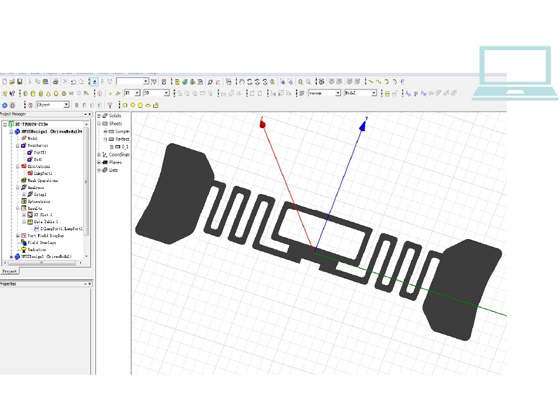

RFID technology is a technology that uses radio frequency signals to automatically identify target objects and obtain relevant data. It is mainly composed of RFID tag, RFID reader and antenna three parts. RFID tags are usually composed of a chip and an antenna, and the unique identification information of the object is stored in the chip. RFID reader transmits radio frequency signals through the antenna, when the RFID tag enters the effective identification range of the reader, the tag antenna receives the radio frequency signal and activates the chip, sends the stored information back to the reader, and the reader transmits the information to the background computer system for processing.

1. Input and track the identity information of turnover box

In turnover box management, each turnover box is assigned a unique RFID tag. This label contains the identity information of the container, such as the number, size, capacity, manufacturer, etc. In the production, warehousing, warehousing, transportation, recycling and other links of the turnover box, the RFID reader will automatically read the information in the label, and the information will be transmitted to the background computer system in real time. In this way, enterprises can monitor the flow direction and status of the turnover box in real time, and achieve visual management throughout the process.

2. Improve logistics efficiency

In the process of logistics, the loading and unloading, sorting and transportation of turnover boxes usually take a lot of time and manpower. Through RFID technology, enterprises can realize the automatic management of turnover boxes. For example, in the loading and unloading process, the RFID reader can quickly read the information in the turnover box label and automatically generate the loading and unloading list, reducing manual operation. In the sorting process, RFID technology can achieve rapid identification and classification, and improve the sorting efficiency. In the transportation process, the location and status of the turnover box can be monitored in real time through RFID technology, optimizing the transportation path and reducing the transportation time and cost.

3. Realize intelligent storage management

In warehouse management, RFID technology can realize the automatic inventory and search of turnover boxes. Through the RFID reader, enterprises can quickly obtain the location and quantity information of all turnover boxes in the storage area to achieve real-time inventory monitoring. When it is necessary to find a specific container, the staff can quickly locate its location through the RFID handheld, improving the search efficiency. In addition, RFID technology can also realize the intelligent management of the storage area, such as automatically updating the shelf location and optimizing the storage layout.

4. Improve the traceability of production quality

In modern logistics and supply chain management, production quality traceability is an important link. Through RFID technology, enterprises can realize the quality traceability of the goods contained in the turnover box. After the RFID tag is installed on the turnover box, the enterprise can record the batch, production date, manufacturer and other information of the goods loaded in each turnover box. When the quality of a batch of goods needs to be traced, enterprises can quickly locate the relevant turnover box and goods information through the background system to improve the accuracy and efficiency of production quality traceability.

The advantages of RFID technology in turnover box management

1, improve data accuracy: RFID technology uses non-contact automatic identification, which can avoid errors and omissions caused by human operation. Through RFID technology, enterprises can obtain the identity information and status information of the turnover box in real time to ensure the accuracy and real-time data.

2, reduce management costs: RFID technology can achieve automated management of turnover boxes, reduce manual operation and time costs. Through RFID technology, enterprises can achieve real-time monitoring and tracking of turnover boxes, reduce the loss rate and damage rate, thereby reducing management costs.

3, optimize the logistics process: RFID technology can achieve real-time tracking and positioning of the turnover box, optimize the logistics process. Through RFID technology, enterprises can monitor the flow direction and status of the turnover box in real time, optimize the transportation path and storage layout, and improve the overall operational efficiency.

4, improve the management level: RFID technology can generate a large amount of data, to provide strong support for enterprise management. Through data analysis, enterprises can understand the use and trend of turnover boxes and develop more scientific management strategies. In addition, RFID technology can also achieve remote monitoring and management functions to improve management level and efficiency.

Actual case

Case 1: Intelligent turnover box management for express companies

A Courier company uses RFID technology to manage turnover boxes. By installing RFID tags on the turnover boxes, the company has achieved real-time monitoring and tracking of the turnover boxes. In the process of express delivery, the staff can quickly read the information in the turnover box label through the RFID handheld machine and upload it to the background system, improving the accuracy and efficiency of express delivery.

Case 2: Recycling packaging management of manufacturing enterprises

A manufacturing enterprise uses RFID technology to manage circular packaging. The company uses recyclable iron packaging containers to replace the disposable wooden boxes used in the material supply process. By installing RFID tags and readers on the circular packaging, the company achieved real-time monitoring and tracking of the circular packaging. In the delivery and reception of circular packaging, circulation, storage, scrapping and other links, the RFID reader will automatically read the information in the label and upload it to the background system. In this way, the company has successfully improved the utilization rate and management level of circular packaging, reducing packaging costs and environmental impact.

RFID technology has shown great application potential and advantages in turnover box management. Through RFID technology, enterprises can achieve real-time monitoring and tracking of turnover boxes, improve logistics efficiency and management level. At the same time, RFID technology can also realize intelligent warehouse management, production quality traceability and intelligent security management and other functions, providing enterprises with more comprehensive and efficient management support. With the continuous development of the logistics industry and the continuous progress of RFID technology, it is believed that the application of RFID technology in turnover box management will be more and more extensive and in-depth.