As an important part of enterprise management, equipment warehouse access management is directly related to the operation efficiency, cost control and material safety of the enterprise. Most of the traditional access management methods rely on paper documents and manual operation, which has some problems such as low efficiency, high error rate and information lag. With the rapid development of Internet of Things technology, RFID (Radio Frequency Identification) technology is increasingly widely used in equipment library access management. This paper will discuss the application of RFID access door in equipment warehouse access management from a professional perspective.

RFID Technology Overview

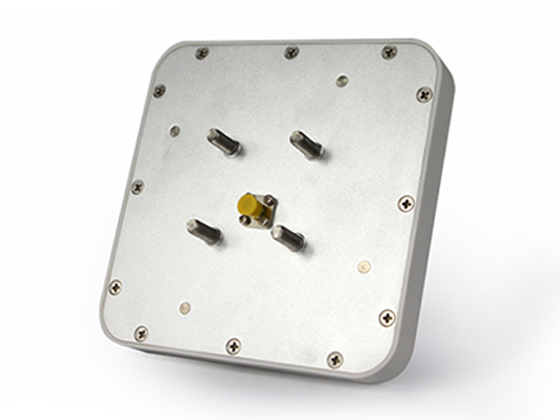

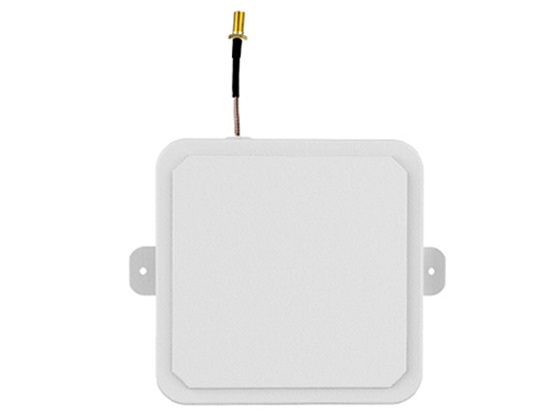

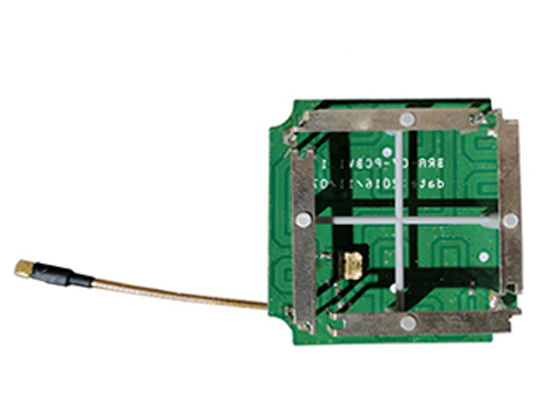

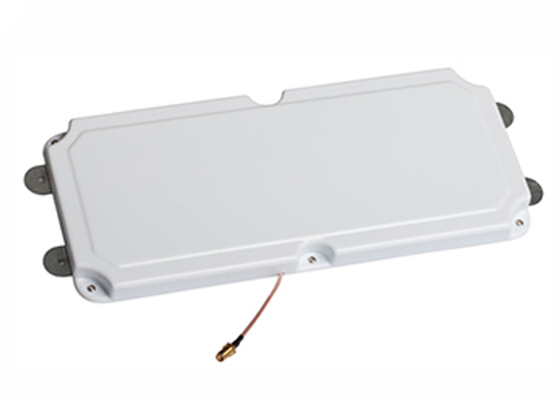

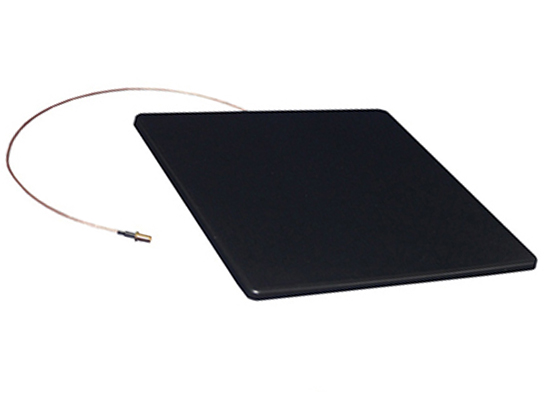

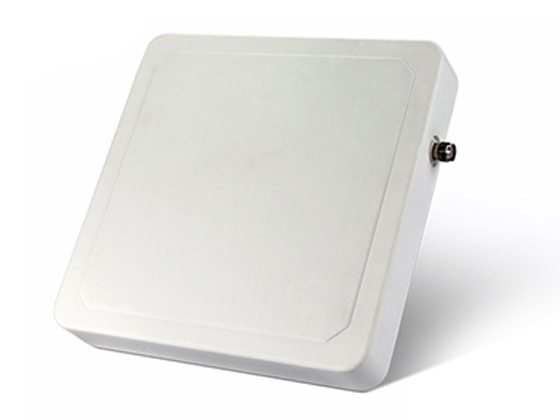

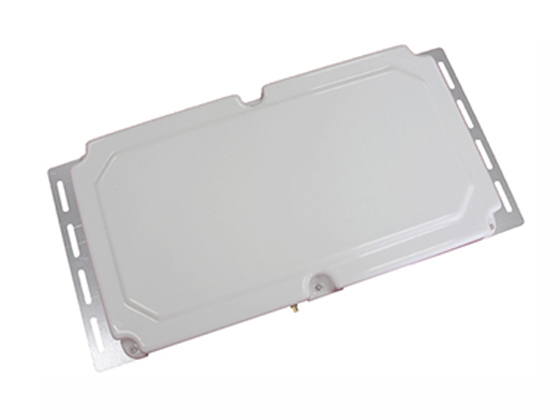

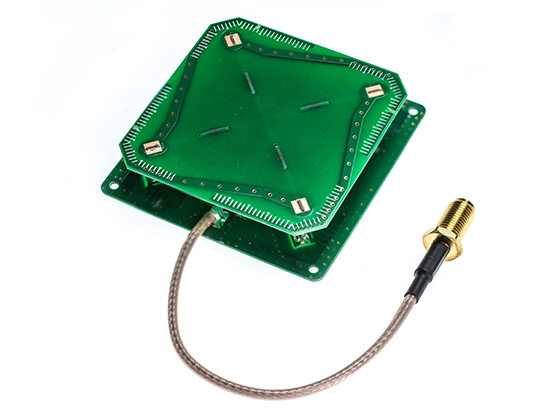

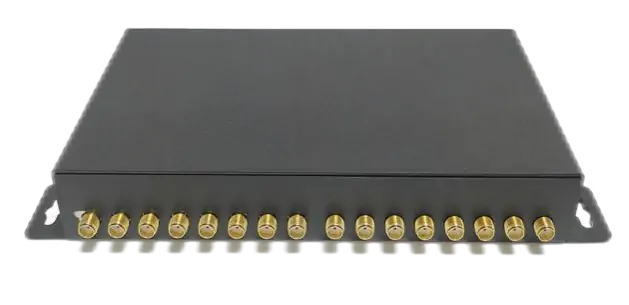

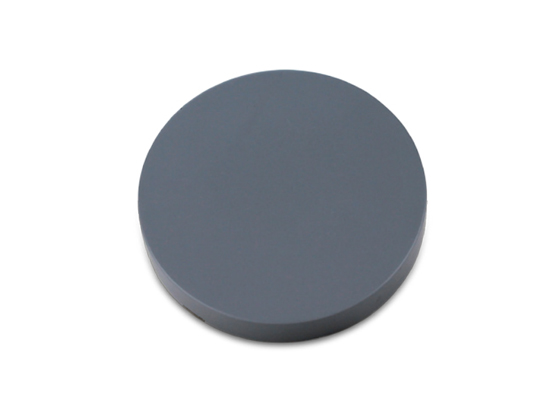

RFID technology is a technology that uses radio frequency signals to automatically identify target objects and obtain relevant data. RFID system is mainly composed of RFID tags, RFID readers and antennas. RFID tags are usually composed of a chip and an antenna, and uniquely identified information is stored in the chip. The reader transmits an RF signal through the antenna to activate the tag and read the information in it. RFID technology has the characteristics of non-contact identification, fast reading speed, large information capacity, strong environmental adaptability, etc., and is widely used in warehousing management, logistics tracking, asset management and other fields.

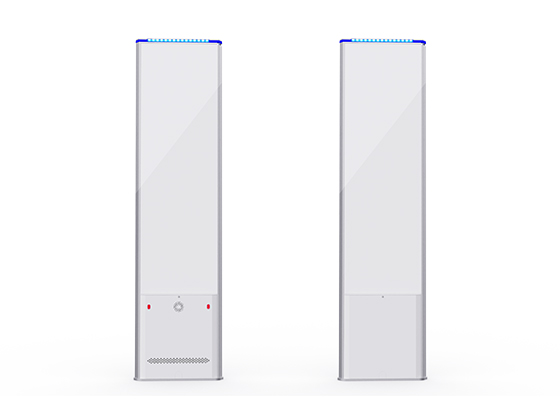

Application of RFID access door in equipment warehouse access management

1. System architecture

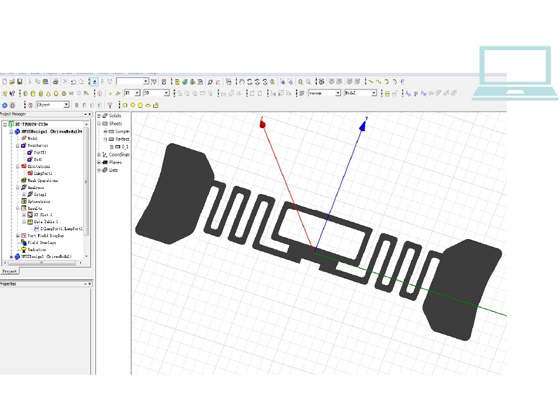

RFID channel door system is usually composed of RFID reader, antenna array, control system, database management system and other parts. RFID readers are installed at the warehouse entrance, and the antenna array covers the channel area to ensure that all equipment passing through the channel can be accurately identified. The control system is responsible for processing the data read by the reader and exchanging data with the database management system to realize the automatic update and management of equipment information.

2. Bind labels

RFID tags and equipment binding is the basis for automated management. Each device is assigned a unique RFID tag before storage, which contains the basic information of the equipment, such as name, model, quantity, production date, etc. The label is usually attached to the device in a prominent and non-damaging position so that the reader can accurately read it.

3. Storage management

When the equipment enters the warehouse through the RFID channel door, the reader automatically reads the label information and transmits the data to the control system. The control system compares the read information with the warehousing plan in the database. After confirming that the information is correct, the equipment information is entered into the database and the inventory record is updated. At the same time, the system can also record the storage time and location of the equipment to provide data support for subsequent management.

4. Outbound management

When the equipment is out of the warehouse, it also needs to pass the RFID channel door. After the reader reads the label information, the control system compares the read information with the outgoing plan. After confirming that the information is correct, the inventory record in the database is updated and the outgoing certificate is generated. The system can also record information such as the time when the equipment is out of storage and the personnel receiving it, which provides a basis for traceability and audit.

5. Real-time monitoring and alarm

The RFID channel door system has real-time monitoring function, which can track the entry and exit status of the equipment in real time, including key information such as location, quantity and time. Once the system detects an abnormal situation, such as unauthorized equipment out of the warehouse, label information mismatch, etc., the system will immediately issue an alarm to remind the management to deal with it. This helps prevent equipment loss, theft and other events to ensure the safety of materials.

6. Data statistics and analysis

The RFID channel door system can automatically generate various statistical reports, such as inventory reports, inbound and outbound reports, etc. These reports provide enterprises with comprehensive data support, which helps enterprises to understand the inventory status, optimize inventory management, and reduce operating costs. At the same time, through the analysis of historical data, enterprises can also predict the future material demand, rationally arrange procurement plans, and improve the response speed of the supply chain.

Advantage analysis

1. Improve work efficiency

RFID channel door system can realize the automatic management of equipment in and out of the warehouse, without manual intervention and manual data entry, which greatly improves work efficiency. The system can update inventory records in real time, reduce the time and cost of manual inventory, and improve the accuracy and timeliness of inventory data.

2. Optimize inventory management

The RFID channel door system can monitor the entry and exit status of equipment in real time, and provide accurate inventory information and material flow. Enterprises can reasonably arrange purchasing plans, production plans and sales plans according to real-time inventory data, optimize inventory management, and reduce inventory overhang and out-of-stock risks.

3. Prevent material loss

The RFID channel door system has an illegal alarm function, and once an unauthorized equipment is detected or the label information does not match and other abnormal situations, the system will immediately issue an alarm to remind managers to deal with it. This helps to prevent the loss of materials, theft and other events to ensure the safety of materials.

4. Improve data accuracy and reliability

The RFID channel door system can quickly and accurately read the information of the RFID tag, avoiding errors and omissions that may be caused by manual operation. The system can automatically update inventory records, reduce human intervention, and improve the accuracy and reliability of data.

5. Realize intelligent management

RFID channel door system can be seamlessly connected with ERP, MES and other enterprise management systems to achieve automatic data exchange and sharing. This helps enterprises achieve intelligent management and improve overall operational efficiency. At the same time, through the deep integration with the Internet of Things, big data, artificial intelligence and other technologies, the system can also achieve more intelligent identification and management functions, and further improve the efficiency of equipment storage management.

The application of RFID channel doors in equipment warehouse access management has brought significant advantages to enterprises, including improving work efficiency, optimizing inventory management, preventing material loss, improving data accuracy and reliability, and realizing intelligent management. Through scientific and reasonable planning and management, RFID channel door system will become an important tool for enterprises to improve operational efficiency, reduce costs and ensure material safety.